The solution

THE SOLUTION

TERRAX MEETS THESE CHALLENGES:

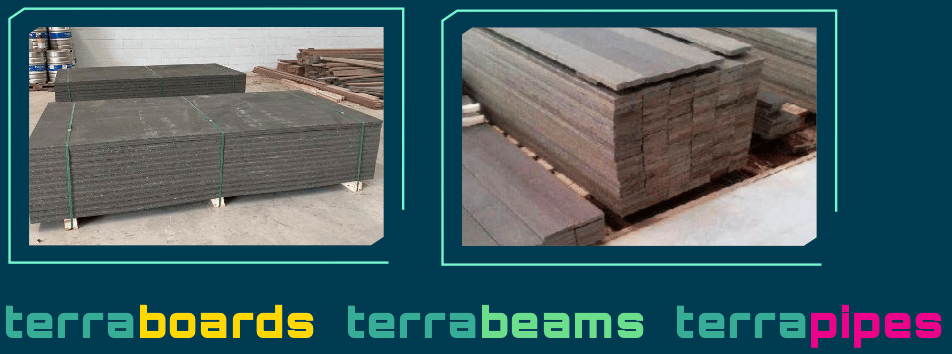

Made from 100% waste that is 100% recyclable - a fully sustainable circular product

THE TERRAX ADVANTAGE:

Like plywood, terrax products can be cut, shaped, sanded, painted, glued and drilled just like wood.

Features and Benefits:

- Strong and durable

- <1% water absorption

- No chemical reaction to acids/concrete

- Can be reused multiple times

- Resistant to abrasion

- Low breakage point on impact

- Stable density

- Immune to termites and bugs

- Dimensional stability in dry & humid environments

- Various colour alternatives

- Thermaformable

- Laminable

- Double-faced

The Process

Terrax’s breakthrough technology makes it possible to combine low grade mixed (commingled) plastic waste with fibrous material without the use of chemical additives.

Terrax can incorporate virtually any natural or man-made fibre: from coconuts to carpeting; and from palm fronds to upholstery.

Usual input materials include PP (polypropylene) scrap, LDPE (low-density polyethylene) scrap and natural fibres, however an adjustment can be made to the formula to meet the requirements of the final product and waste availability.